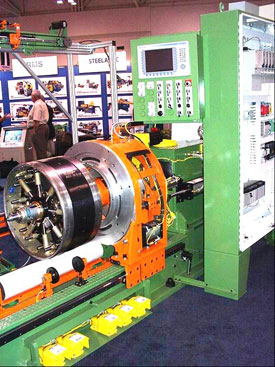

Tire Building Equipment

RRR roots are founded in supporting the equipment needs of the tire industry. Located 10 minutes from Akron, we've worked closely with the leading tire manufacturers providing research and development of new processes/equipment and complete turnkey solutions. We build both 1st stage and 2nd stage tire machines and supporting equipment. We also provide comprehensive equipment refurbishment services where we completely disassemble the entire machine, replace all worn parts, reassemble and run off.

Known as the tire drum specialists, we have become the industry leader in tire drum building and rebuilding.

Various tire equipment built to customer specifications:

- 1st Stage Tire Building Machines

- 2nd Stage Tire Machines

- Continuous Strip Cutter/Feeders

- Band Builders

- Batch-off machines

- Bead Flipping Machines

- Mill Blenders

- Sidewall Buffers

- Guillotine Cutters

- Slab Cutters

- Fabric Processing Machines

- Mill Aprons

- Mill Feed Conveyors

- Mill Strip Blenders

- Ply Guides and Wind-ups

- Belt & Tread Servicers

- Rolled Stock Servicers

- Turret Type Servicers

- Sewing Machines

- Carcass Stitchers

- Tread Slitters

- Stock Let-off's

- Tread Jammers

- Gazuit Bias Cutters

Tire Machine Replacement Parts

- First Stage Tire Building Machines

- Second Stage Tire Building Machines

- Force Variation Machines

- Air Drums

- BRC Equipment

- Pass & LT Truck Radial & Bias First Stage Tire Building Machine

- Large Industrial Radial & Bias First Stage Tire Building Machine

- Small Industrial & Airplane Tire Building Machine

- Motorcycle Radial & Bias First Stage Tire Building Machine

- Racing Radial & Bias First Stage Tire Building Machine

- Passenger & LT Truck Second Stage Tire Building Machine

- Passenger & LT Truck Single Stage Tire Building Machine

- Motorized Laser Line Light Systems

- Rolled Sidewall Auto Cut and Apply Servicer/Cassettes

- Rolled Tread Auto Cut and Apply Servicer/Cassettes

- Rolled Tread Cassette Windup

- Innerliner and Body Ply Servicer/Cassettes

- Chafer/Abrasion Strip Applier

- Booked Tread Servicer

- Book Tread Replacer (Auto Cut to Length)/Cassette

- Low Profile Back Stitcher

- TOSW Static Stitcher/SWOT Option

- Transfer Rings

- 2nd Stage Universal Bladderless Drum

- 2nd Stage Mechanical Beadlock Drum

- 2nd Stage Breaker & Tread Drum

- Single Stage Mechanical Bead Lock Drum

- Industrial/Airplane Drums 4 Thru 12 Inch

- Drum and Tooling Qualification Stand

- Passenger/LT Truck/Racing Bead Luber

Akron Standard Parts

We provide quotations for replacement parts and new machines. These include:

- 36" Continuous Strip Feeders/Cutters (feeds continuous strip of rubber to cold feed extruder)

- Skid Conveyors

- 44" and 52" Mill Feed Conveyor

- Batch-off Slitter Sub-assemblies

- Bias Cutters

- Impression Marker Kits for marking rubber stock on Batch-off equipment

- 11W Industrial Tire Building Machine redesigned and significantly improved to a new Model #2000-I-412-428.

- Off The Road Tire Building Machines

Some of the former Akron Standard products that we support are:

- Continuous Strip Cutter/Feeders

- Band Builders

- Batch-off machines

- Bead Flipping Machines

- Mill Blenders

- Sidewall Buffers

- Guillotine Cutters

- Slab Cutters

- Fabric Processing Machines

- Mill Aprons

- Mill Feed Conveyors

- Mill Strip Blenders

- Various equipment built to customer specifications

- Ply Guides and Wind-ups

- Belt & Tread Servicers

- Rolled Stock Servicers

- Turret Type Servicers

- Sewing Machines

- Carcass Stitchers

- Tread Slitters

- Stock Let-off's

- Tread Jammers

- Gazuit Bias Cutters

- Off The Road Tire Building Machines (300 and 400 Series)

Inside Tire Building Machine